2024-03-02

[public] 176K views, 13.0K likes, dislikes audio only

Head to https://squarespace.com/hyperspacepirate to save 10% off your

first purchase of a website or domain using code HYPERSPACEPIRATE

Original Ethylene production video:

Board Schematic:

https://drive.google.com/file/d/1jGZg0plUJJzqGkXVEZyQ5Ky7ZHtwXC8n/view?usp=sharing

Arduino Code:

https://drive.google.com/file/d/12d2MGy-z9415vCw4UUFIL6S_Q7bAi6pA/view?usp=sharing

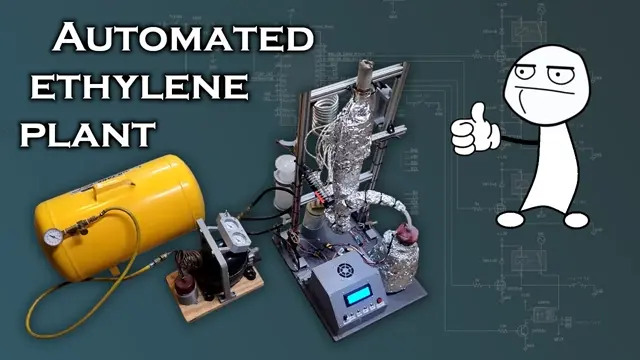

In this video I'll show how I automated the process of producing

Ethylene (C2H4) gas for use as a refrigerant. Ethylene is known as

Ethene, but is different from Ethane which is C2H6.

My original process used a manually controlled flame from a propane

burner to heat a catalyst pipe full of aluminum oxide to decompose

ethanol vapor into Ethylene and water vapor and fill a beach ball

with the Ethylene gas, which I'd later pump into a tank under

pressure.

This process was time consuming, inefficient, and required constant

attention to keep the flame at the right level to maintain

temperature. I use a lot of Ethylene gas to test refrigerant mixes

for my cryocooler, so it was worth the time to make the process

hands-off.

The new catalyst pipe is a 1-3/8" x 24" aluminum tube with 8 135W

band heaters clamped to it. 1/4" aluminum tubes are brazed to the

catalyst pipe to serve as the inlet / outlet. The band heater section

is insulated to maintain temperature, but the ends of the pipe are

exposed to keep them cooler to avoid melting the aluminum brazing

alloy.

The temperature of the catalyst pipe is controlled by a PWM signal

from an arduino to a solid state relay driving the band heaters, with

feedback from a thermocouple in the middle of the pipe. The target

temperature I used in this video was 450C. Lower temperatures will

make a higher percentage of Diethyl Ether, and higher temperatures

will create Hydrogen and Carbon, and possibly damage the catalyst

pipe.

The ethanol vapor is supplied by a 1L boiler which is quickly brought

up to its boiling temperature with a 100W heater and then sustained

by a 30W heater. Feedback for the boiler heater control is provided

by a thermistor inside the boiler. If the temperature inside goes

over the boiling point of the ethanol, the program assumes the liquid

has been depleted, and shuts off.

The average production rate of Ethylene gas is around ~40L/hr

depending on the temperature used for the reaction.

One issue i ran into early on was that I used denatured alcohol from

the hardware store, which i discovered was up to 60% methanol. This

still creates Ethylene, but it also creates several other Alkenes

from CH2 chains. I solved this problem by using Bio-ethanol, which

appears to be azeotropic 96% ethanol without additives.

The ethylene is automatically pumped into a pressure tank when the

gas pressure pushes up the piston of a 500 ml syringe until the

piston trips a limit switch that triggers a compressor to turn on.

At the time of this video's making, I've created nearly 1,000L of

ethylene gas, a lot of which i've liquefied for cryogenic

experiments.

Later, this gas will be filtered, dried, then used as refrigerant in

a cascade vapor compression system, and as a component in my mixed-

gas joule-thomson cryocooler.

Music Used:

Kevin MacLeod - Bossa Antigua

Kevin MacLeod - Lobby Time

Kevin MacLeod - George Street Shuffle