2011-08-22

[public] 91.5K views, 1.14K likes, 8.00 dislikes audio only

I've been cutting glass plates and mirrors with my CNC milling machine machine for years. In this video, I describe a few tips and the general technique that I use.

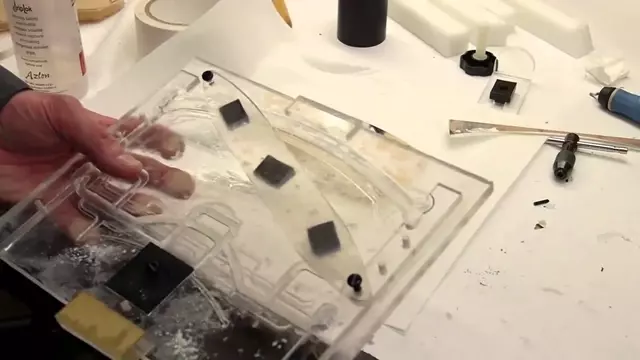

Clamping the glass plate to the table is the critical part of the process, and so I built a jig that allows the glass to be held laterally with shims, but does not require a high clamping force, which would crack the glass.

Cutting parameters:

.085" dia diamond burr

3000 RPM

1-3 inches per minute feed

Cut depth .130" (full material thickness)

Flood coolant with soluble oil cutting fluid

http://benkrasnow.blogspot.com/2011/08/cnc-milling-glass-plates-and-mirrors.html

http://benkrasnow.blogspot.com/2008/08/cnc-milling-glass-plates-and-mirrors.html

/youtube/video/HyI111Tn0Cs?t=37.66

/youtube/video/HyI111Tn0Cs?t=89.290001

/youtube/video/HyI111Tn0Cs?t=109.57

/youtube/video/HyI111Tn0Cs?t=186.7