2023-09-10

[public] 206K views, 10.4K likes, dislikes audio only

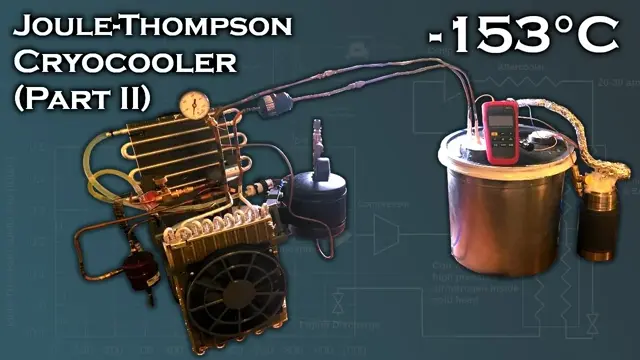

In this video, I'll build on my progress from the last Joule-Thomson

cryocooler video and reach a temperature of -153C on a single stage

using parts sourced from window A/C units and common/cheap substances as

refrigerants (a mixture of Propane, Ethylene, and Methane). This

temperature is low enough to condense any gas except for Hydrogen,

Helium, or Neon, at the following pressures:

Nitrogen - 25.3 barA (352 PsiG)

Air - 20.2 barA (278 PsiG)

Oxygen - 10.3 barA (135 PsiG)

Methane - 1.9 barA (13 PsiG)

I tested several different mixtures to achieve this temperature, but the

best performing I've found so far has been a 30/20/50 blend of Propane,

Ethylene, and Methane, respectively. The Propane comes from an ordinary

grilling tank, the Ethylene is produced by heating denatured alcohol

over a catalyst, and the Methane comes from residential natural gas. All

these sources are very cheap.

For a throttling valve to achieve the Joule-Thomson effect, I use a 1m

long 1mm ID capillary inline with a computer-controllable electronic

expansion valve (EEV) used for fine-tuning flow resistance. I avoid

using *only* an EEV due to the relatively large thermal conduction

losses experienced through the bulky metal valve body.

The system is charged with 180 PsiG (11.3 BarA). With the EEV wide open,

the high/low side pressure is ~400/65 psiG (28.6/5.5 barA) respectively.

With the EEV closed as far as possible without shutting off the flow,

the high/low side pressure is ~520/10 psiG (36.9/1.7 barA) respectively.

A temperature drop of 20-35°C across the EEV+capillary restriction is

typical.

I use a vacuum enclosure to thermally insulate the cold end of the

system, but since I can't reach a vacuum much higher than about ~2 mBar,

the vacuum isn't a very effective insulator, so I still had to pack the

enclosure and wrap the heat exchanger coil with glass wool. Research

papers on this subject claim pressures on the order of 10^-4 mBar inside

the vacuum enclosure, which I'm unable to produce.

While the temperature I've achieved is low enough to make liquid

nitrogen / oxygen / methane under pressure, the heat exchanger I

assembled to do so on the cold end was ineffective, so I didn't liquify

any gas in this video.

In the next part of this series, I'll focus on mixture optimization (by

adding varying percentages of Butane and Nitrogen or Argon to the mix),

increasing cooler power / temperature drop by use of a pre-cooler, and

construction of a cold head that incorporates a large "reservoir" for

accumulating several hundred CC of liquified gas before discharge to

atmospheric pressure.

If this project is succesful in producing decent quantities of liquid

Nitrogen, I'll turn my focus toward production of Liquid Hydrogen using

a Joule-Thomson system with LN2 pre-cooling.