2025-09-19

[public] 73.5K views, 7.03K likes, dislikes audio only

Click this link https://boot.dev/?promo=HYPERSPACEPIRATE and use my code HYPERSPACEPIRATE to get 25% off your first payment for boot.dev.

Also, a big thanks to Digital Properties Group (https://dpgsupply.com/) for giving me some pointers on building my Oxygen Concentrator and supplying me with 13X sieve and a big air compressor.

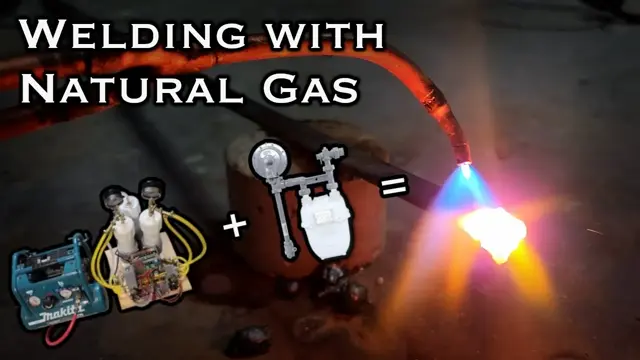

Picking up where I left off with my 1,500W HHO torch video, I'm once again trying to devise a way to gas weld without buying oxygen and acetylene. While the HHO torch could cut, the big drawback was that it wasn't possible to weld because the water vapor exhaust caused immediate oxidation of the metal being heated. To try to get around this, I'll attempt to use residential natural gas or propane in conjunction with an oxygen concentrator to weld.

The carbon content of the methane or propane fuel is sufficient to reduce the amount of oxidation that occurs and actually make a usable weld, but it's still pretty difficult to use for welding compared to acetylene. This is because methane/propane burn at around 2800C with oxygen, while Acetylene burns at around 3200C, so it can heat an area much faster. Perhaps the bigger issue is that the water vapor content of a methane flame is 2/3 (by mole), whereas with Acetylene it's only 1/3. I think this difference in water vapor content is enough to dramatically affect the quality of the weld.

This is still a very useful tool for a home shop, because it can be used to cut, braze, solder, melt glass, etc. In that respect, it fulfils the same purpose as the HHO torch, but can provide significantly more heating power for the same quantity of electricity, and costs less money to build. It avoids the need for handling highly corrosive Sodium Hydroxide electrolyte solution.

*NEVER* attempt to install / modify equipment on a residential gas line unless you know exactly what you're doing. Make sure the space you're working in is well ventilated and free from ignition sources / static electricity, and always ensure the gas valve is shut off before connecting new equipment. Before using new equipment, use soapy water to do a leak check on the gas connections to make sure there's no gas getting out.

If you have any hesitation about your ability to handle natural gas, don't do it. This system works just as well with a tank of Propane or LPG with a regulator, like what you'd use for a grill.

So, while this isn't that great as a welder, its other abilities make it a worthwhile tool around the shop, and avoiding the need to refill oxygen bottles can actually save huge amounts of money in the long run depending on what kind of work you're doing. This oxygen concentrator will be used in future projects to make LOX with a new cryocooler I'm building, and to crystalize YBCO in an oxygen furnace.

Music Used:

Kevin MacLeod - Lobby Time

Kevin MacLeod - Backbay Lounge